As plastic waste pollution becomes increasingly severe, replacing traditional plastic bags with environmentally friendly alternatives has become an inevitable trend. Non-woven T-shirt bags are a modern, convenient, and sustainable packaging solution, widely trusted by businesses, retailers, and distribution systems today.

1. What are non-woven T-shirt bags?

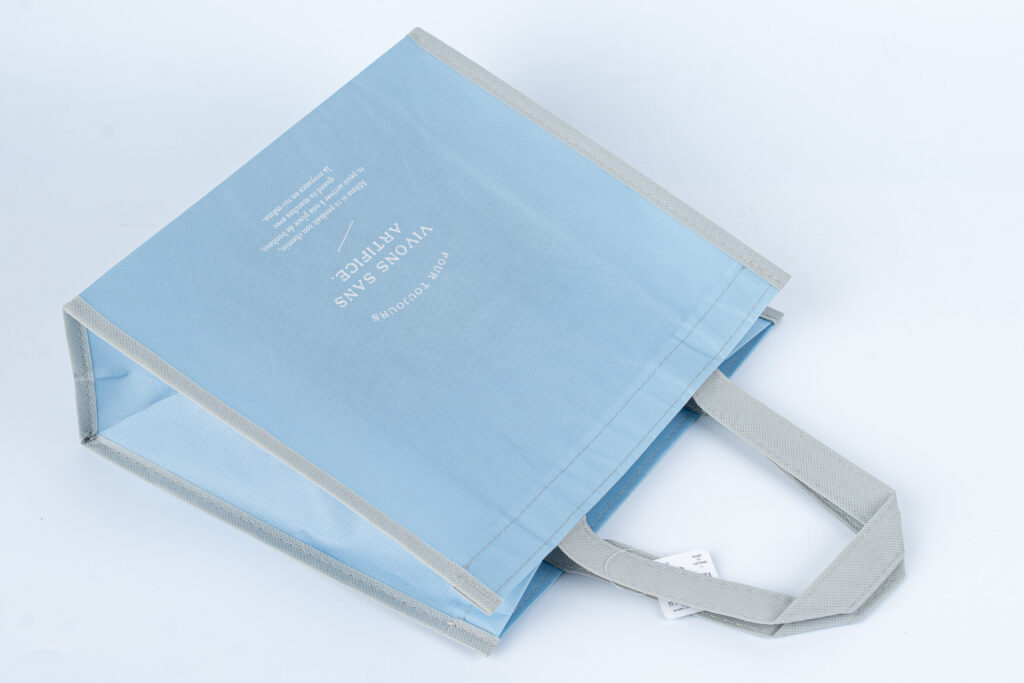

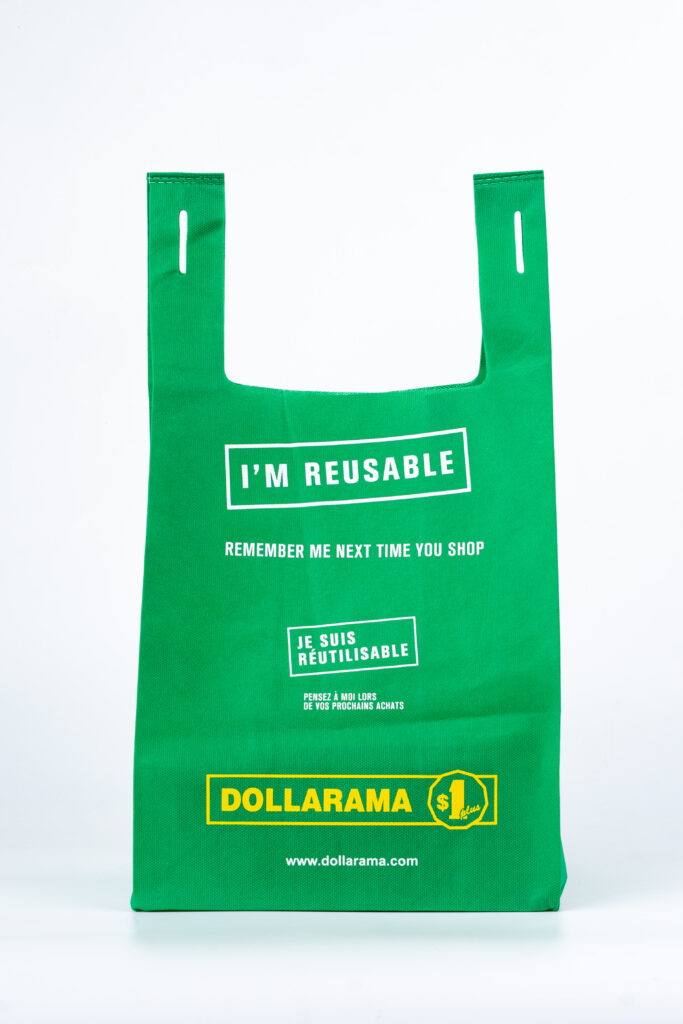

Non-woven T-shirt bags feature an integrated handle design similar to a T-shirt shape and are made from high-quality non-woven fabric. This material is lightweight yet highly durable, offers excellent load-bearing capacity, and can be reused multiple times, helping to significantly reduce plastic waste and its impact on the environment.

Thanks to their compact and practical design, non-woven T-shirt bags are commonly used in supermarkets, convenience stores, fashion shops, trade fairs, events, and promotional campaigns.

2. Key advantages of non-woven T-shirt bags

2.1. Durable and environmentally friendly material

Made from premium non-woven fabric, these bags are stronger and more tear-resistant than conventional plastic bags. They also offer better biodegradability, helping to minimize negative environmental impact.

2.2. Reusable – cost-effective solution

Unlike single-use plastic bags, non-woven T-shirt bags can be reused many times without tearing or losing shape. This not only supports environmental protection but also reduces long-term packaging costs for businesses.

2.3. Easy logo printing & brand recognition

The smooth, flat surface of non-woven fabric allows for clear, sharp, and eye-catching printing of logos, slogans, and brand images. This makes the bags an effective marketing tool that naturally enhances brand visibility.

2.4. Light water resistance – easy to clean

The bags provide light water resistance, helping to protect the contents inside. After use, they can be easily wiped clean and dry quickly, saving time and effort.

2.5. Convenient T-shirt handle design

The integrated T-shirt-style handles make the bags comfortable to carry and easy to use. Their lightweight and practical design suits a wide range of applications, from everyday shopping to large-scale events.

Stavian Green Packaging – A trusted supplier of non-woven T-shirt bags

Stavian Green Packaging is proud to be a professional manufacturer and supplier of high-quality non-woven T-shirt bags, serving diverse needs from individual customers and retail stores to large enterprises.

We offer:

– A wide range of sizes, colors, and thickness options

– Solutions suitable for various industries such as retail, food, fashion, events, and exhibitions

Discover our products here: https://greenbags.stavianpackaging.com/products/t-shirt-bag/