As the world intensifies efforts to reduce plastic waste and transition toward a circular economy, PP plastic packaging (Polypropylene) is increasingly proving its essential role. Thanks to its outstanding properties such as safety, durability, reusability, and high recyclability, PP packaging is widely regarded as one of the most suitable materials for long-term sustainable development.

Today, many countries are enforcing stricter environmental regulations on the packaging industry. In this context, PP packaging has emerged as an effective solution that not only meets functional requirements but is also more environmentally friendly than many traditional plastic materials.

1. What is PP packaging ?

PP (Polypropylene) is a thermoplastic polymer known for its lightweight nature, high mechanical strength, and excellent resistance to heat and impact. Most importantly, PP is non-toxic and safe for users, making it suitable for a wide range of applications—from heavy industrial packaging to everyday consumer products.

Thanks to these advantages, PP plastic packaging helps to:

– Reduce single-use packaging

– Extend product life cycles

– Minimize plastic waste generation

– Promote reuse and recycling

As a result, PP packaging is becoming the preferred choice for businesses pursuing green growth and sustainable development strategies.

2. PP woven fabric – A durable solution for industrial packaging

PP woven fabric stands out for its excellent load-bearing capacity and superior durability. With a tightly woven structure, this material is widely used in industrial packaging applications where strength and safety are critical.

Common PP woven fabric products include: Agricultural packaging bags, cement bags, fertilizer bags, chemical packaging bags, jumbo bags (FIBC)

Beyond industrial use, PP woven fabric is also increasingly applied in consumer and retail markets, such as: PP woven shopping bags (market bags, supermarket bags), advertising and promotional bags, reusable fashion bags

These products are not only strong and long-lasting but also easy to print with logos and branding, helping businesses enhance brand visibility effectively.

3. PP non-woven fabric – Lightweight, versatile, and eco-friendly

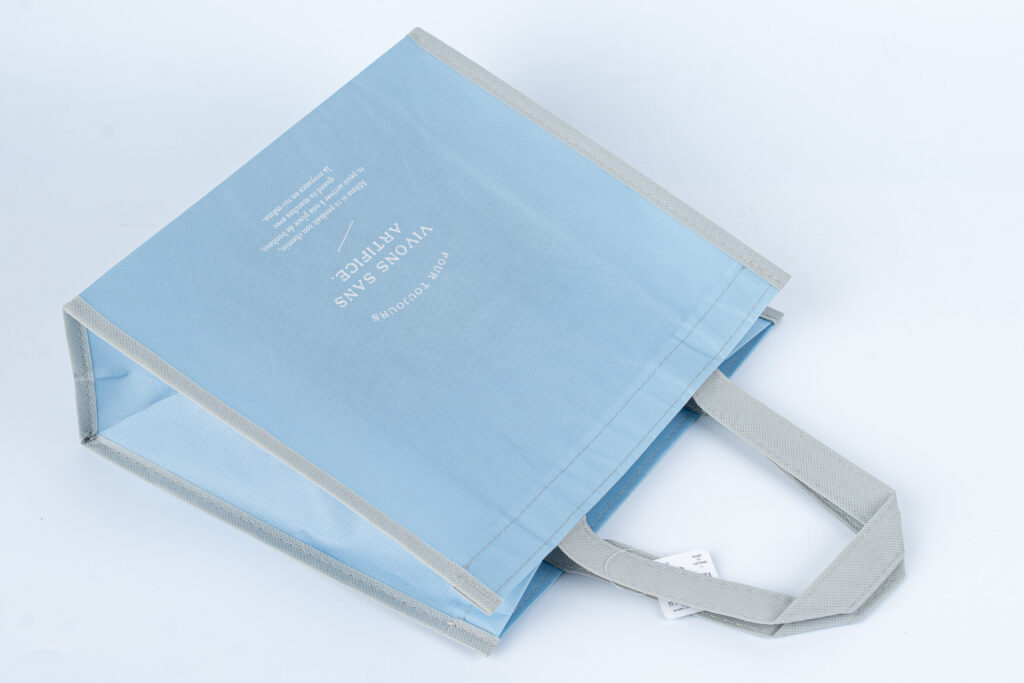

Alongside woven fabric, PP non-woven fabric plays a vital role in modern consumer packaging. Lightweight, soft, easy to shape, and environmentally friendly, PP non-woven fabric is especially popular for products designed for end consumers.

Typical applications of PP non-woven fabric include: Reusable shopping bags, promotional and giveaway bags, event and conference bags

With its attractive appearance, easy processing, and reasonable cost, PP non-woven packaging enables businesses to convey a green message while leaving a positive and professional impression on customers.

Thanks to its flexibility and wide range of applications, PP plastic packaging is steadily gaining market dominance. Beyond meeting diverse usage needs, PP aligns well with environmental policies and long-term sustainability goals adopted by businesses worldwide.

Comprehensive PP packaging solutions from Stavian Green Packaging

Are you looking for high-quality PP packaging solutions? Stavian Green Packaging proudly offers a wide range of PP woven and PP non-woven fabric products in various sizes, colors, designs, and thicknesses – meeting all usage and brand promotion needs.

Discover more our products here: https://greenbags.stavianpackaging.com/products/